- We promise

- To add value to your business process

- To reduce your costs

- To help you grow in a sustainable way

- Because improvement never stops

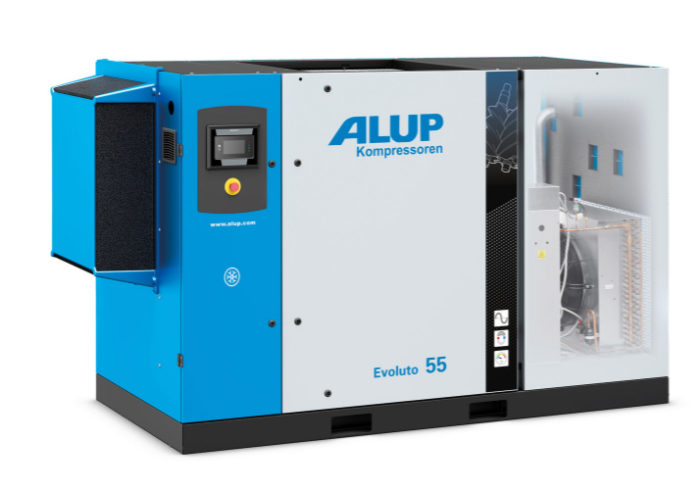

INTERIOR PERMANENT MAGNET (iPM) MOTOR

- IE4 Super Premium Efficiency

- IP66, highest possible protection against dust ingress

- In-house designed

- Oil-cooled, optimal cooling at all speeds (4)

New screw compressor element

- Superior performance and efficiency

- Improved rotor profile, reduced pressure losses

- In-house designed and produced in Belgium

New integrated direct drive transmission

- Coupling-free design, minimal transmission losses

- Maintenance-free for low total cost of ownership

SOLID INLET BAFFLE WITH RADIAL FAN

- Small installation footprint, unit can be placed against a wall

- Filters mats pre-filter incoming air, ensuring superior air quality

- Highly efficient and low noise radial fan as standard

Airlogic² T TOUCHSCREEN CONTROLLER

- State-of-the-art, maximizing user-friendliness, efficiency and reliability

- Large 4,3” full-colour touchscreen display and 30+ languages

- Integrated connectivity with remote monitoring possibilities

- Full insight into network helps optimizing and save energy

Icons

- Connectivity is the future. The Evoluto 45-75 comes fully prepared:

- Remote monitoring that helps you optimize your compressed air system and save energy

- On-time maintenance which optimizes costs and ensures a longer machine life

- Potential problems are recognized before they can pose a threat to the continuity of your production

VARIABLE SPEED TECHNOLOGY

- Robust industrial design with IP5X protection

- Tailor-made for screw compressor applications

- In-house designed

SEPERATE COOLERS

- Separate oil and air cooler for high-quality cooling and long lifetime of the coolers

- Gliding rails for easy and safe removal

- Easy access for cleaning

QUALITY FILTRATION

- Protecting internal components and increasing lifetime

- Heavy duty air/oil/oil separator filters with long lifetime for low total cost of ownership

OIL SEPARATOR VESSEL

- Integrated minimum pressure valve (MPV) eliminates risk of leakage

- Long lifetime thanks to cast iron parts

- Designed for optimal oil separation and low oil carry over

- In-house designed

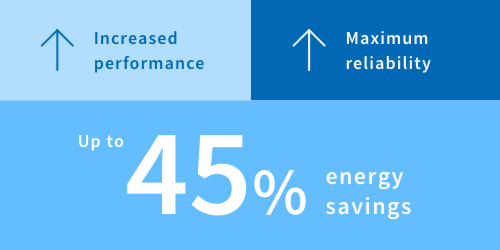

A big leap in energy efficiency

Why energy efficiency?

Energy costs represent about 70% of the total operating cost of your compressor over a 5-year period.

Why variable speed compressors?

By matching the air supply to the air demand, unload losses are avoided, and energy costs reduced on average by 30%.

Why invest in Evoluto?

Imperium variable speed technology combined with iPM motor technology and evolved the energy efficiency of variable speed compressors to a new level, resulting in energy savings of up to 45%.

Built-in options

Service plan

Scope XT

Technical data

The Alup Promise

We commit ourselves to understand your business and needs and to constantly improve your business processes. We will use all our technological and human resources to make your business more profitable and sustainable.

Evoluto 45

Working pressure

Min. free air delivery (7 bar)*

Max. free air delivery

Motor power

Noise level**

Cooling air volume

Weight

Compressed air output diameter

Evoluto 55

Working pressure

Min. free air delivery (7 bar)*

Max. free air delivery

Motor power

Noise level**

Cooling air volume

Weight

Compressed air output diameter

Evoluto 75

Working pressure

Min. free air delivery (7 bar)*

Max. free air delivery

Motor power

Noise level**

Cooling air volume

Weight

Compressed air output diameter

* Unit performance measured according to ISO 1217, Annex C, latest edition.

** Noise level measured according to ISO 2151 with optional baffle.

All technical data for air-cooled machines without integrated dryer. For technical data of water-cooled machines or machines with integrated dryer, please contact your local salesforce.